Foundation Repair Concrete Repairman® We Fix It Right™

Licensed, Bonded and Insured Commercial & Residential Foundation Repair Contractors - ROC# 300512 CR-9

Foundation Repair Concrete Repairman® We Fix It Right™

Licensed, Bonded and Insured Commercial & Residential Foundation Repair Contractors - ROC# 300512 CR-9

High warehouse traffic and moving heaving loads back and forth can really take its toll on your concrete floor. This type of activity can put added stress on the control joints that hold your floor together and keep it level. Fork lifts and fork trucks moving heavy pallets through out your warehouse and loading docks can cause un-level surfaces which will begin to effect the condition of your equipment.

Replacing forklift tires / wheels is expensive, buying or replacing fork trucks is expensive as well and can slow production and through put. Theses pieces of equipment work and last longest if they are used on solid level surfaces.

Avoid downtime and excessive repair cost and contact us today and let us take care of you warehouse floors. We are concrete floor experts and we have the right and affordable solution to keep you up and running with minimal cost or down time.

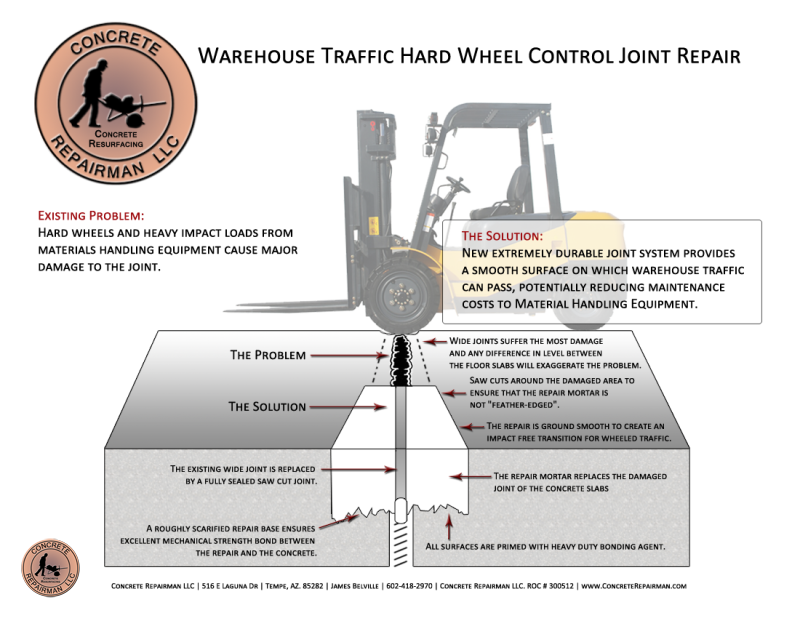

Hard wheels and heavy impact loads from materials handling equipment cause major damage to the control joints.

Wide joints suffer the most damage and any difference in level between the floor slabs will exaggerate the problem greatly.

Our new extremely durable joint system provides a smooth surface on which warehouse traffic can pass, potentially reducing maintenance costs to Material Handling Equipment such as forklifts and fork trucks.

ooo

Concrete floor control joint repairs need to be repaired by using the best repair methods possible, for any industrial or warehouse floor repair. Call The Experts at Concrete Repairman LLC. 602-418-2970

Epoxy Joint Filler

Epoxy Joint Filler After Floor Grinding

After Floor Grinding Close-Up Pic of Control Joint Repair

Close-Up Pic of Control Joint RepairAll control joints need the right joint filler to have the chance to hold up to the severe stresses from the weight transfer from one floor slab to the next. This type of stress at the control joint, will cause joint failure from the vertical movement over time. Hard tire forklifts will chip, crack, and damage both sides of the joint, causing down time to repair hard forklift wheels. The repair method used by Concrete Repairman starts with floor grinding. Grinding the concrete slab joint enables the best transfer of weight smoothly across the joint. Grinding and leveling floor joints also properly profiles the surface of the concrete slabs to allow for best adhesion for joint filler products at the same time.

Overview of Floor Joint Repair

Overview of Floor Joint Repair 10 Days of Use

10 Days of Use Joint Sealant, Epoxy Joint Filler and Grinding Heaved Floor Repair

Joint Sealant, Epoxy Joint Filler and Grinding Heaved Floor RepairAll concrete surfaces are profiled to the correct profile for best adhesion and molecular attachment to the vertical sides and top of control joints. The best repair method is; Grinding both sides of the control joint using vertical cutting diamond blades penetrating to a depth of equal value as the width of the joint. Usually 3/4 width cut, and 1″ depth is used to open this type of joint open. Joint Filler Epoxy is also supported by using silica sand, to fill voids in the vertical break of the slab below where the epoxy is filled. Without this support, the control joint filler will fail from the vertical weight of the hard tired forklifts rolling across it.

Joint Filler and Floor Grind After

Joint Filler and Floor Grind After After Photo of Completed Repair

After Photo of Completed Repair Final Photo of Floor Joint Fill and Grinding Heaving Floor Joint

Final Photo of Floor Joint Fill and Grinding Heaving Floor JointAfter the install of the control joint filler or epoxy joint fill, the access is then ground to the same elevation as the adjacent floor slabs. This type of repair method is then considered complete. The discoloration of the concrete from grinding, overtime will blend in with the existing floor slabs. The most important consideration with this type of industrial warehouse floor joint repair is; The joint filler, or epoxy joint fill has to be flexible enough and at the same time, be able to hold up the vertical pressures being applied. Most all concrete repair contractors do not understand this type of repair because they don’t understand all of the necessary steps to make the best repair possible. Call the Concrete Repairman at 602-418-2970 to schedule a estimate for your Commercial warehouse or industrial floor crack, control joint fill, or repair today

Warehouse Floor Epoxied Joint Fill

Warehouse Floor Epoxied Joint Fill Warehouse Floor Repair 50,000 Sq Ft.

Warehouse Floor Repair 50,000 Sq Ft. Repaired Heaved Commercial Floor

Repaired Heaved Commercial FloorConcrete heaved joints become loose mainly because they lack an effective load transfer device such as dowels, tie bars, or reinforcing steel. Other factors include excessive curling or warping, high drying shrinkage, and wide temperature swings. The size and cost of floor joint repairs can be kept to a minimum if the damage is detected and repaired at an early stage. Regular inspections should be made to check that the existing joint sealant is doing its job to protect and maintain the floor joint. Once the damage has been allowed to progress beyond the scope of re-sealing the joint, it will be necessary to reconstruct the joint. Our heavy duty repair mortar is specifically intended for use on industrial floor to repair floor joint damage quickly and with minimum disruption to the ongoing operations. Wide joints increase the risk of spalling due to the deflection of the joint sealant under load. It is therefore important to reduce the width of the joint opening at surface level. Our tried and tested floor joint repair solution allows a wide ‘traditional expansion joint’ to be replaced with a neat wide, fully sealed saw cut. Each of our floor joint repairs are ground smooth and flush with the adjacent floor surface to ensure that wheeled traffic has a smooth transition over the repaired joint. Most warehouse and industrial floors will have joints with spalled edges and this should be seen as an early indication of more serious potential long term damage. The floor joint edges are vulnerable to damage and tend to ‘spall’ under the impact from hard wheeled traffic. Our floor joint sealant is rigid enough to provide support and protection to the concrete floor, but also flexible enough to accommodate any opening of the joint and still remain bonded to at least one face of the concrete slabs. Concrete Repairman’s 2 part epoxy joint fill is a 100% solids semi-rigid epoxy joint filler used to protect saw cut joints in concrete slabs or in repair of existing damaged joints. This epoxy absorbs the impact and shock of heavy loads and steel wheeled traffic, preventing erosion of control joint edges. Our epoxy joint filler is available in Regular Cure (RC) 24-48 hours cure @ 75ºF, Fast Cure (FC) 12-24 hours @ 75ºF, and Super Fast Cure (SFC) 10-20 hours @ 75ºF, formulations. Concrete Repairman LLC. provides services and consultations on material selection, specification, troubleshooting, and other information on the proper repair and protection of concrete surfaces. Concrete Repairman LLC. is available to assist you in any floor problems. Warehouse Floor Joint Repair weight transfer across a construction joint on warehouse floors can damage the slabs on both sides. As the weight of forklift moves across the joint, one slab section is lower than the next slab that is about to carry the load, causing the hard tire wheel to chip the side of the joint. Over time this damage grows and begins to cause even more damage to occur faster. For forklift operators, I is a very bumpy ride, and cause accidental products to shift off the pallets the forks are carrying. Call The Concrete Repairman at 602-418-2970

Commercial Warehouse Floor Control Joint Repair, Joint Fill and Grind

Commercial Warehouse Floor Control Joint Repair, Joint Fill and Grind Forklifts can now run full production mode faster

Forklifts can now run full production mode faster We repair commercial, and warehouse heaving joints better than any company in Arizona

We repair commercial, and warehouse heaving joints better than any company in Arizona– Foundation Repairman | Serving the Greater Phoenix Metro Areas Including –

Ahwatukee | Buckeye | Casa Grande | Chandler | Gilbert | Glendale | Goodyear | Mesa

Paradise Valley | Phoenix | Queen Creek | Scottsdale | Sun City | Sun City West | Tempe

Your Foundation Repairman Arizona

Stem Wall Foundation Repair & Inspection

Post Tension Foundation Repair & Inspection

James Belville – (602)418-2970

Foundation Repair Expert – Concrete Repairman®

Concrete Repairman LLC – a fully licensed, bonded and insured foundation repair company serving customers in Phoenix and surrounding areas in Arizona. We have over 30 years of experience installing and repairing home foundation cracks, floor crack structural stitching, floor leveling, stem walls, post tension, monolithic and resurfacing foundation damage for homeowner, and commercial clients in Arizona.